how to do a brinell hardness test|brinell hardness number chart : store The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to . webWelcome to the JTV Go app! With the JTV Go app, you can watch JTV live with our hosts plus shop current on-air items and previously shown products. Shop the day's best .

{plog:ftitle_list}

webO The Noite é um talk show apresentado por Danilo Gentili e vai ao ar de segunda a sexta nas madrugadas do SBT. Personalidades de todas as áreas são entrevis.

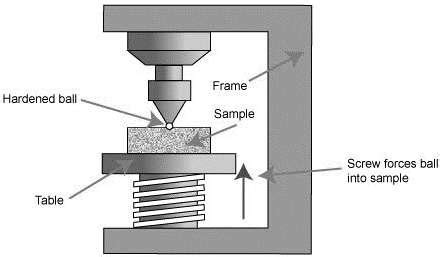

The Brinell hardness test formula. When measuring hardness using the Brinell method, a hardened steel or carbide ball of known diameter under a known load is forced into the . Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition . There are two methods to perform the Brinell hardness Test on the metal as follows: Standard Method. Non-Standard Method. Standard Brinell Hardness Test: Brinell Indentation Diagram.The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to .

The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested .

https://engineers.academy/This video outlines how a Brinell hardness test is conducted, as well as explaining how to calculate a value for the Brinell hardne.Learn how to use Brinell hardness test units and testing machines to quickly and accurately assess large samples with a coarse or inhomogeneous grain structure – with knowledge and insight from Struers, the world’s leading .

DIN Abrasion Tester traders

For softer materials or materials with coarse microstructures – the Brinell hardness test is suitable. When you require precise measurements for materials with high hardness or thin coatings – the Vickers hardness test is suitable.

The Brinell method can be used for testing non-homogeneous materials (e.g. castings), because the large ball comes into contact with many crystals (different metallographic .A chart is then used to convert the averaged diameter measurement to a Brinell hardness number. Test forces range from 500 to 3000 kgf. A Brinell hardness result measures the permanent width of indentation produced by a carbide . In the Brinell hardness test, we use a small ball (the indentor) made of tungsten carbide or steel to penetrate the material's surface, leaving a hemispherical indent. From the load/pressure on the indentor and the diameter of the hole it makes on the material surface, we can calculate its Brinell hardness number. .

The Brinell hardness test is not suitable for very hard materials or hardened surface layers because the ball does not penetrate sufficiently into the material. Higher test loads are not the solution at this point, as this leads to .

Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. This test reveals vital information about their hardness, toughness, and suitability for specific applications by subjecting materials to controlled indentation.The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically.An alternative method is the Brinell hardness test, which uses a hardened steel (or tungsten carbide) ball indenter with a diameter D of, usually, 10 mm.This is applied under a load P of 500–3000 kg applied for 10–30 s.The diameter of the circular indentation d is measured in millimetres. The hardness number, (HB) is calculated using the following equation:The Brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The test is achieved by applying a known load to the surface of the tested material through a hardened steel ball of known diameter. The diameter of the resulting permanent impression in the tested metal is measured and the Brinell Hardness .

The Brinell hardness test is a standardized test used for measuring the hardness of metals and other hard materials. Do not know how to perform a Brinell Hardness test? This is an article to teach you detailed Brinell Hardness tests procedure on various materials. + 86 755 61301520;Concluding a hardness test using a popular method like the Brinell hardness test requires measuring the indentation left on the material surface by the load applied. Though several other hardness testing methods are available, the Brinell hardness test and how to read and represent its values are why we’ve written this guide.

The HRB scale typically is used for soft materials such as aluminum and brass alloys. It uses a 1/16-in. ball indenter with a 100-KG test force. Brinell Testing. Brinell testing normally is used for larger, heavy-walled pipe. Because the Brinell test is not a depth-measuring technique, it is more forgiving. Hardness testing methods: Rockwell, Brinell and microhardness Heat treating has evolved into a highly complex, precise process that improves characteristics of metal parts. A critical component of quality heat treating is employing the correct hardness testing method to show manufacturers their parts achieve design requirements.Application of Brinell Hardness Test. Due to the wide number of ball sizes and loads available, it is possible to test a very wide range of hardness values using the Brinell method. As the Brinell test uses relatively high loads, and therefore relatively large indent, it is frequently used to determine the hardness of the material which has .https://engineers.academy/This video outlines how a Brinell hardness test is conducted, as well as explaining how to calculate a value for the Brinell hardne.

For instance, converting from a Rockwell hardness test on the C scale (HRC) to a Brinell hardness test value requires using the formula: BHN = 5.970 x (HRC + 104.7). This formula gives an approximate value for the Brinell hardness value, and quality assessment professionals use it to create the conversion tables and charts for instant conversion.In the Brinell hardness test, an optical method, the size of indentation left by the indenter is measured. In contrast to the likewise optical Vickers method,which involves a pyramid-shaped indenter being pressed into a specimen, the Brinell method uses a spherical indenter. The Brinell hardness test is used to determine hardness and is done by forcing a hard steel or carbide ball indenter of a specified diameter onto the test metal surface under a specified load. This is followed by measuring the diameter of .

Reciprocating Friction Tester traders

These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to .

Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and aluminium alloys, while the 3000 N load is often used for testing harder materials such as steels and cast irons.However, the general rule is that the combination of test load and ball diameter .

The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials. .Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter .The typical brinell hardness test uses a 10 millimeters (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29 kN; 6,600 lbf) force. For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. The indentation is measured and hardness calculated as:

Rubber vulcanizing Tester traders

The Brinell hardness test uses a spherical indenter, while the Rockwell hardness test uses either a diamond cone or steel ball indenter. Another difference is the amount of force applied to the surface of the material. The Brinell hardness test typically uses a higher load than the Rockwell hardness test.The Brinell hardness test also uses a microscope to measure the indents made by the indenter. For this reason, the Brinell scale is more accurate than the Rockwell scale. However, using the Brinell hardness test method is more expensive because of the optical measurement system setup. The Rockwell method is easier and faster, making it cheaper . 1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information .

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .

As stated above, Brinell hardness testing is performed using a Brinell hardness tester (of course!); the machine that presses the indenter ball into the sample. The load is applied for several seconds to ensure maximum plasticity of the indentation (or, to put it another way, to prevent the metal, at a microscopic level, ‘pulling itself .Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load).

brinell hardness tester diagram

WEB8 de jul. de 2017 · Como colocar música no Carros Rebaixados Brasil - Novo jogo para qualquer celularDownload do Jogo Carros Rebaixados Brasil --- http://bit.ly/2ttJpux

how to do a brinell hardness test|brinell hardness number chart